Great Technologies

need great

materials

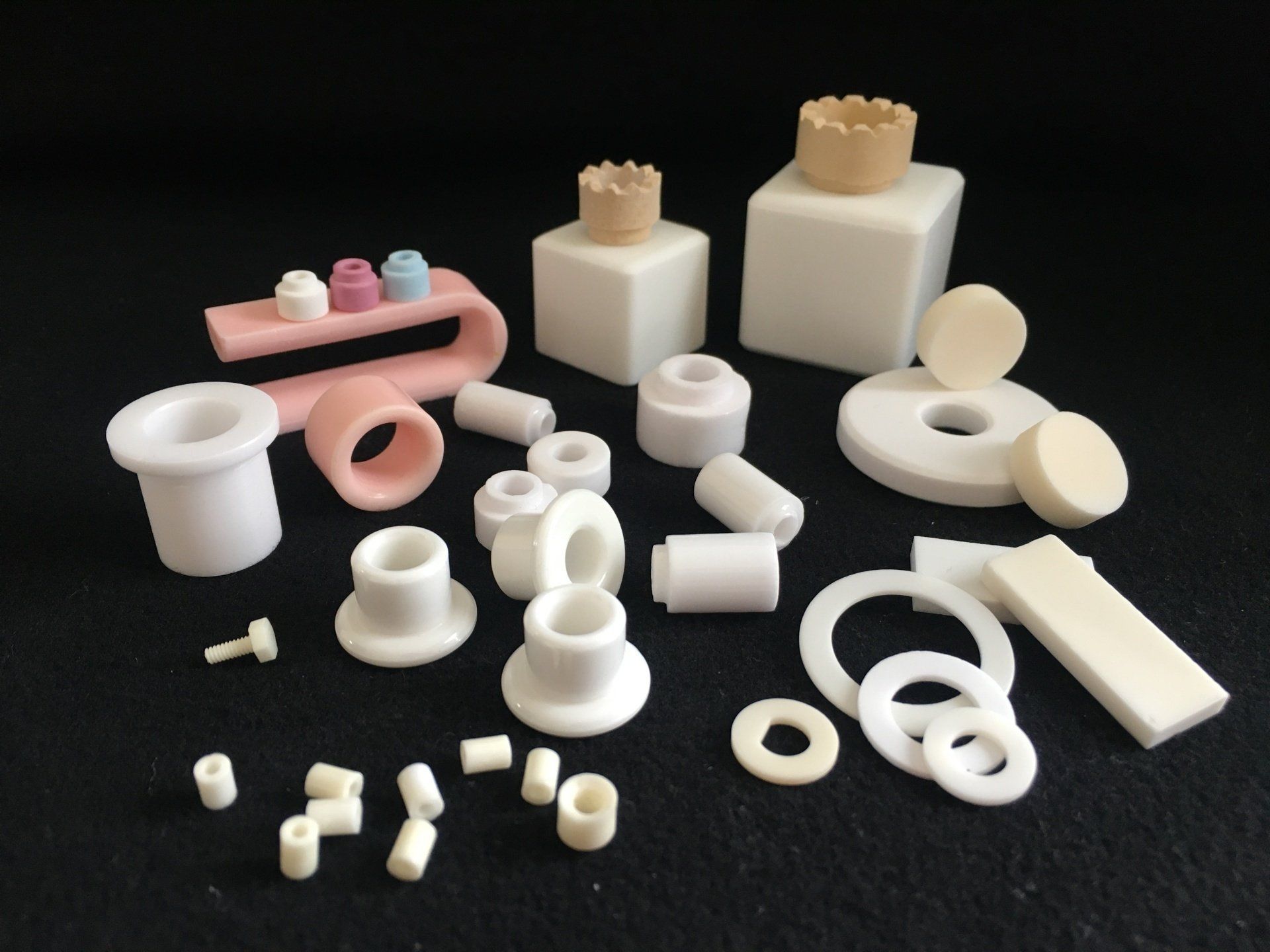

Aluminum nitride ceramics - semi-finished products, plates, rods, processing according to drawings

Buy aluminum nitride ceramic components from experts and benefit from our many years of experience in the production of technical ceramics.

We process aluminum nitride ceramics from small quantities for prototypes to series production.

Due to the special properties of aluminum nitride (AlN), this ceramic is used in various technical fields of application. Due to its extremely good thermal conductivity of 180 W/mK, the sintered ceramic material has become indispensable in power electronics. Aluminum nitride is of particular interest in places in components or machines where heat needs to be dissipated as quickly as possible, but the material has electrical insulation.

Properties of aluminum nitride ceramics:

Melting point: 2400°C

Breaking strength: 300 - 400 MPa

E-Modul: 350 GPa

Thermal expansion coefficient: 4.63 * 10^-6 (up to 1900°C)

Thermal conductivity: 180-220 W/mk

By using different manufacturing processes, we are able to respond quickly and easily to the wishes of our customers.

We have been a permanent and respected partner for national and international companies as well as research institutes and universities for years. In addition to sales and consulting, we also participate in further developments and support our customers in complex projects.

We manufacture aluminum nitride ceramic components on customer request according to drawings, but we can also fall back on a stock of aluminum nitride AlN ceramic plates, rods and rods.

Prototypenbau:

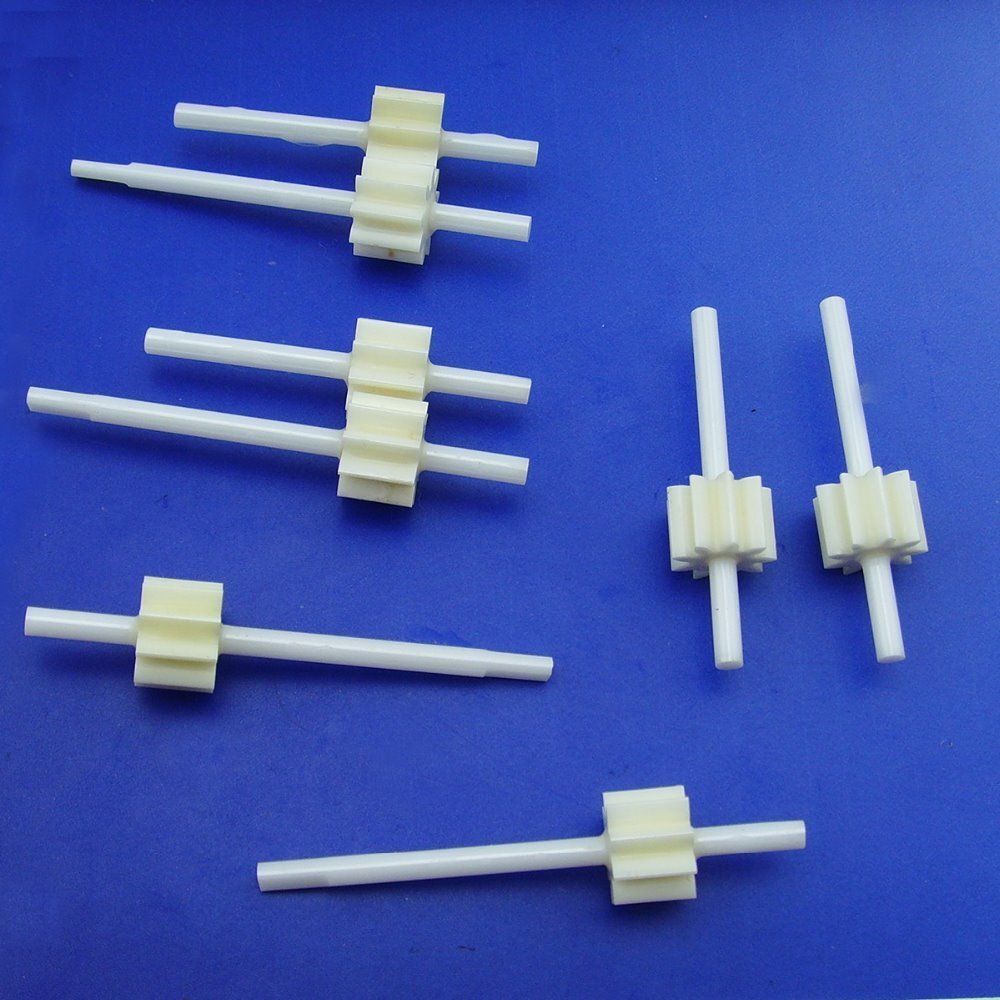

Through the use of individual manufacturing processes that are adapted to the batch size, we are a strong partner in prototype construction. We manufacture your aluminum nitride ceramics according to drawings from a quantity of 1 with a short production time. For smaller quantities, we mill the aluminum nitride ceramic component from the full semi-finished product and, if necessary, process it by precision grinding. As with aluminum oxide ceramics, aluminum nitride plates can also be laser cut.

Series production:

We can realize small and large series of aluminum nitride ceramic components after the prototype phase with short delivery times.

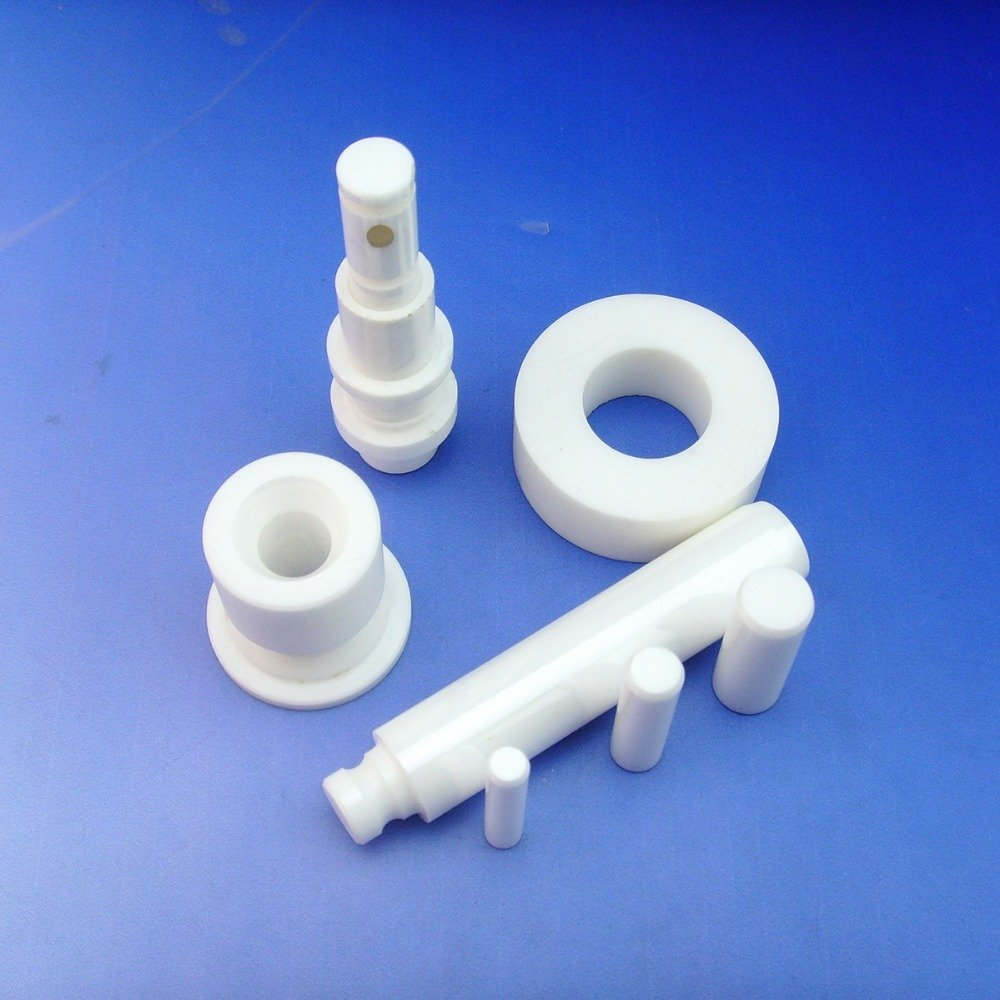

Common aluminum nitride ceramic components (manufacture according to drawing):

- insulators

- bushings

- Filter

- heating elements

- Screws and nuts

- Knife cutting

Aluminum nitride ceramic production and processing - from sintering to the finished component

Aluminum nitride AlN components are manufactured in several steps.

Like other technical ceramics, aluminum nitride components are manufactured by sintering. For this purpose, a mold is made that presses the green body. Depending on the component geometry and requirement profile, the green compact can be further processed. The green body is sintered at 1800°C for several hours.

Finally, we process the finished sintered component with diamond tools in order to be able to achieve tight tolerances.

However, due to the hardness of the sintered aluminum nitride, machining requires some experience. In addition to manufacturing by sintering and lasering, we also have the option of lasering aluminum nitride ceramic plates up to a thickness of 4mm.

Talk to us and let us advise you on the multitude of manufacturing options.

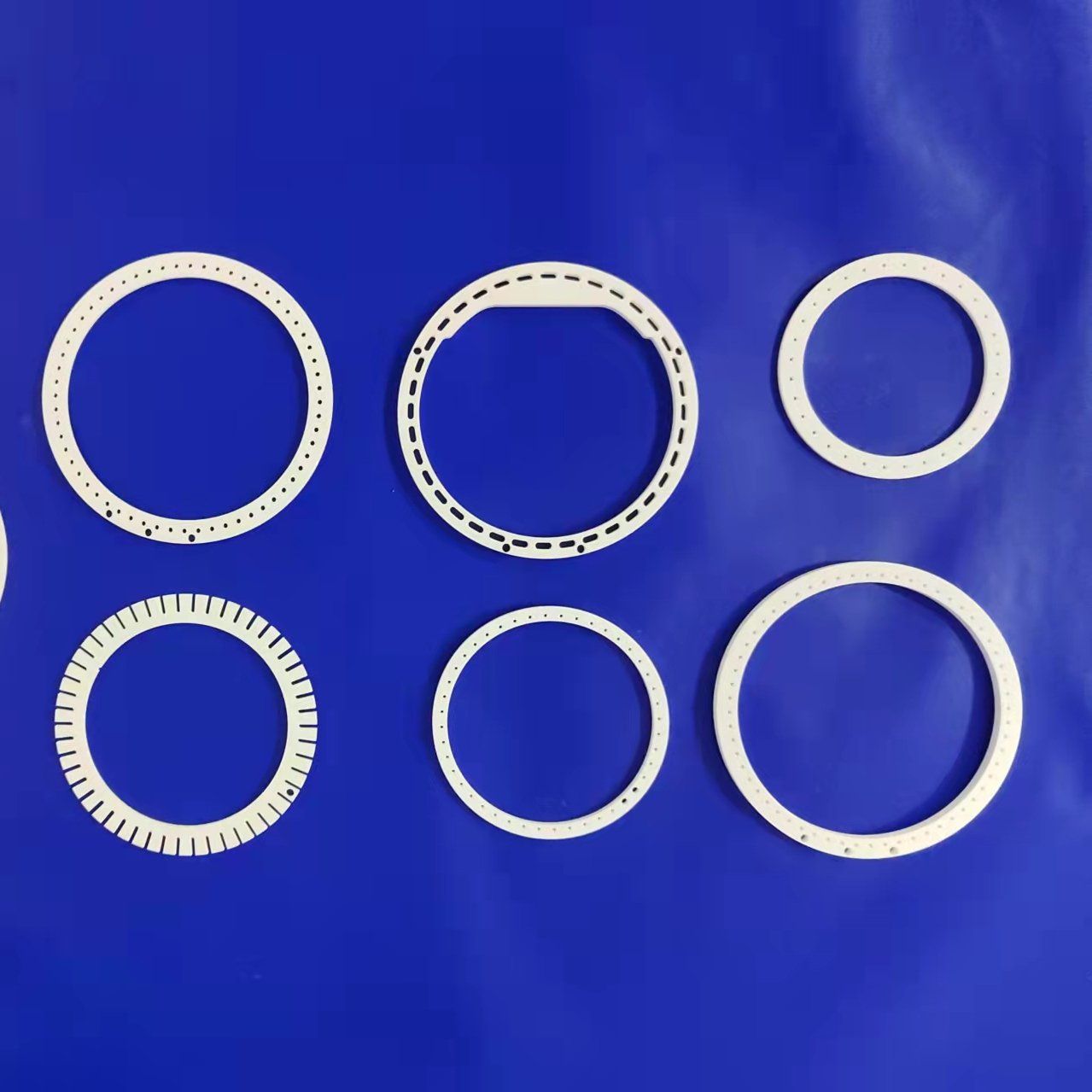

Aluminum nitride ceramic plates

HME-Tech has specialized in the production of aluminum nitride plates.

In addition to standard dimensions, we offer customer-specific oversize panels from a thickness of 1mm. The achievable dimensional accuracy in the thickness tolerance is /- 0.005mm.

Aluminum nitride plates are used, among other things, as sintering bases when ceramic plates made from other materials are unsuitable for the sintered material.

Due to the good thermal conductivity of aluminum nitride, the plates are also often used as an underlay substrate to quickly dissipate heat and isolate parts from each other.

Do you need holes or contours in aluminum nitride plates? We have the possibility to cut sintered plates up to a thickness of 4mm with the laser. Learn more about the numerous possibilities of laser processing aluminum nitride here.

Send us your request by email or use the contact form:

Send us your request by email or use the contact form: