Great Technologies

need great

materials

Boron nitride components manufacturing and processing

We manufacture boron nitride components according to drawings - work with the experts when it comes to boron nitride processing

In addition to the production of boron nitride components, we process boron nitride by milling, turning and grinding. We are therefore able to quickly produce small quantities for prototypes and are your competent partner for series production.

Before you start designing and planning your boron nitride components, here is some important information about this special material, which can convince in many areas thanks to its different properties depending on the manufacturing process:

Boron nitride occurs in three modifications α, β, γ.

Only the white α-boron nitride BN occurs naturally and has a hexagonal structure.

β and γ boron nitride do not occur naturally and are produced synthetically under high pressures.

During production, the hexagonal structure changes to a cubic structure.

Hexagonal boron nitride can be assigned to graphite and cubic boron nitride to diamond.

Accordingly, the properties of natural and synthetic boron nitride are also different.

The natural white α-boron nitride is soft and has good thermal conductivity and good sliding properties.

The β and γ boron nitride, on the other hand, is black and extremely hard. It is known as CBN and is often used as the cutting edge of tools to machine hard materials.

What are the properties of the most common α boron nitride?

Color white

Specific gravity: 2.26 g/cm³

Operating temperature: can be used up to 900 °C in air, in an inert atmosphere even up to 2,100 °C

Resistant to oxidation: 980°C-1030°C

Melting point: 2,700°C

Electrical insulation: good

Thermal conductivity: up to 400 W/m*K

Gliding properties: good, even at high temperatures

We look forward to your inquiry and would be happy to advise you:

Boron nitride bushings and sleeves

Boron nitride bushings and sleeves offer major advantages over other materials.

On the one hand the excellent insulation of the material but also the good heat conduction and gliding properties.

We process boron nitride bushes by turning, milling and grinding according to the customer's drawing requirements. From small quantities for prototypes to series production, we supply you with products of the highest quality.

Do you have a custom-made boron nitride sleeve with high tolerances or special surface properties? No problem, please send us your request.

Manufacture / process boron nitride crucibles and nozzles

Do you need boron nitride crucibles and nozzles?

We produce boron nitride crucibles and nozzles from small quantities for your development project and are your competent partner in series production.

How can boron nitride be machined?

Different processing options can be considered for the processing.

We can mill, turn and grind components, depending on the quantity, boron nitride components can also be manufactured in one mold.

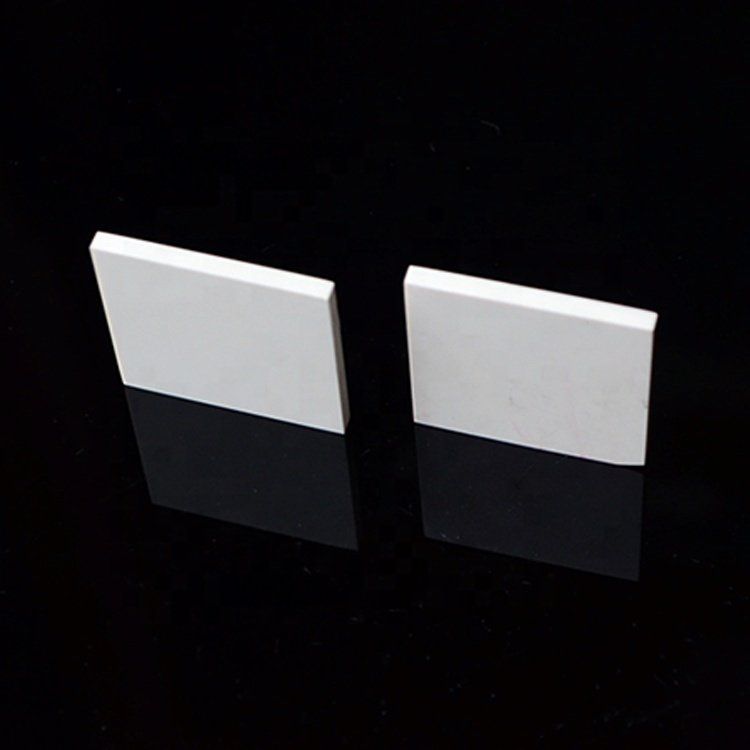

Boron nitride sheets for insulation or underlay

Boron nitride is excellently suited as underlays and insulating panels in furnaces or plants.

Boron nitride plates are insulating, extremely thermally conductive and non-wetting.

They can therefore be used as a base plate in soldering or sintering processes if the component or the solder should not stick. Boron nitride plates are also often used as protective plates in welding robots to protect other components from welding spatter.

We produce the panels according to customer requirements and process them by milling and grinding.

Machining of boron nitride components such as bars, rods and tubes

Boron nitride tubes are ideal as protective tubes.

Especially when heat is to be dissipated quickly, but the protective jacket must be insulating.

Boron nitride does not have a wetting effect, so the tubes, rods and rods can also be used in areas where welding is done or the material comes into contact with solder.

In addition to simple tube and rod geometries, we process your components according to drawings and provide them with shoulders, threads or holes.

Boron nitride is easy to process, and nothing stands in the way of any geometry.

Send us your request by email or use the contact form: